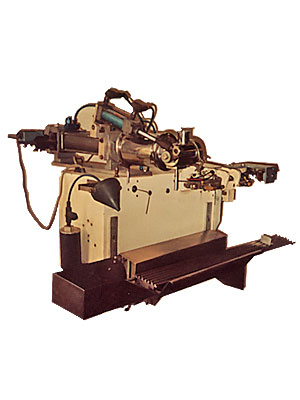

The machine is fitted with:

SPVL machines are built to withstand difficult operating conditions. The steel frame is painted to protect against all corrosion attacks. All components in contact with the product are made from high quality stainless steel, buffed finish. SPVL model is compact and requires minimal servicing.

For this usage, the machine is fitted with volumetric dosing pump. The dosing pump is fitted with a rotary valve system and an anti-drip filling nozzle. The volume to be filled is adjusted by changing the pump stroke.

| Capacity | 20 to 250 ml or 100 to 1000 ml |

|---|---|

| Production rate | 350 to 1000 pouches per hour depending on volume and nature of the product to be filled |

| Maximum Sealing Length | 200 mm |

| Electricity | 110V/220V, Single Phase, 50 HZ, AC 1 KW |

| Compressed Air | 10 m³/Hour at 6 kg/cm² |

| Chilled Water | Consumption = 50 litres per hour at 10-15°C in closed circuit |

| Coding System | Coding by hot embossing on pouches. To mark price, month & year of filling or any other variable information. |

| Sealing/Capping System | Impulse sealing followed by chilled water cooling or capping system on pet bottles |

| Dimensions | 110 X 110 X 145 cms |