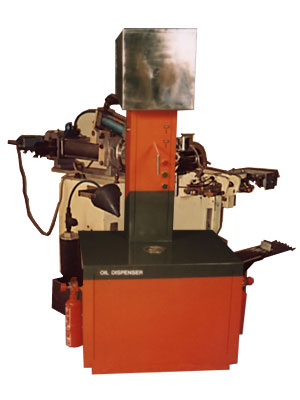

To dispense liquid from bulk quantity (from tank/200 litres barrel) to small quantities. This is a customer friendly dispensing machine ideal for retail sale outlets. It also serves as an advertising point.

| Dispensing Range | 500 and 1000 ml/Others optional |

|---|---|

| Output/Rate of dispensing | 400 fills and 250 fills per hour/ Depends on Range of Fillings |

| Power | 220 V AC Single Phase 50 cycles, 2 KW |

| Size | 640 mm x 760 mm x 1600 mm |

| Compressed Air | 10 m³/Hour at 6 kg/cm² |

| Chilled Water | Consumption = 50 litres per hour at 10-15°C in closed circuit |

| Coding System | Coding by hot embossing on pouches. To mark price, month & year of filling or any other variable information. |

| Sealing/Capping System | Impulse sealing followed by chilled water cooling /capping system on pet bottles. |

| Dimensions | 110 X 110 X 145 cms |