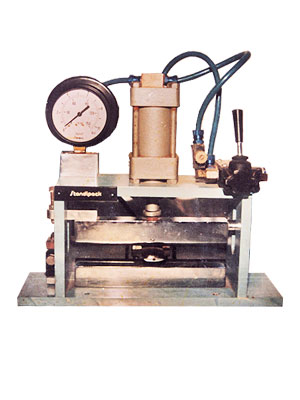

The compact machine is designed for balloon testing of all types of pouches ranging from 20ml to 1000 ml.

The machine is made of high Quality Aluminium Material and its pneumatic parts are of NUCOON or PESTO make.

Complete machine is carefully Packed in the wooden box before dispatching.

Dry compressed air, up to 6 Kgs/Cm² from the compressor is to be connected to INLET of F.R. (Flow Regulator) for Air Pressure Control of the machine.

| Problem | Check Point |

|---|---|

| Machine does not operate. | Check the Air Pressure. Check the Pneumatic Cylinder. |

| Machine not working properly. | Check Rubber in Jaws. Set Air Pressure. Check Pressure Gauge. Check Pneumatic Limit Switch. |